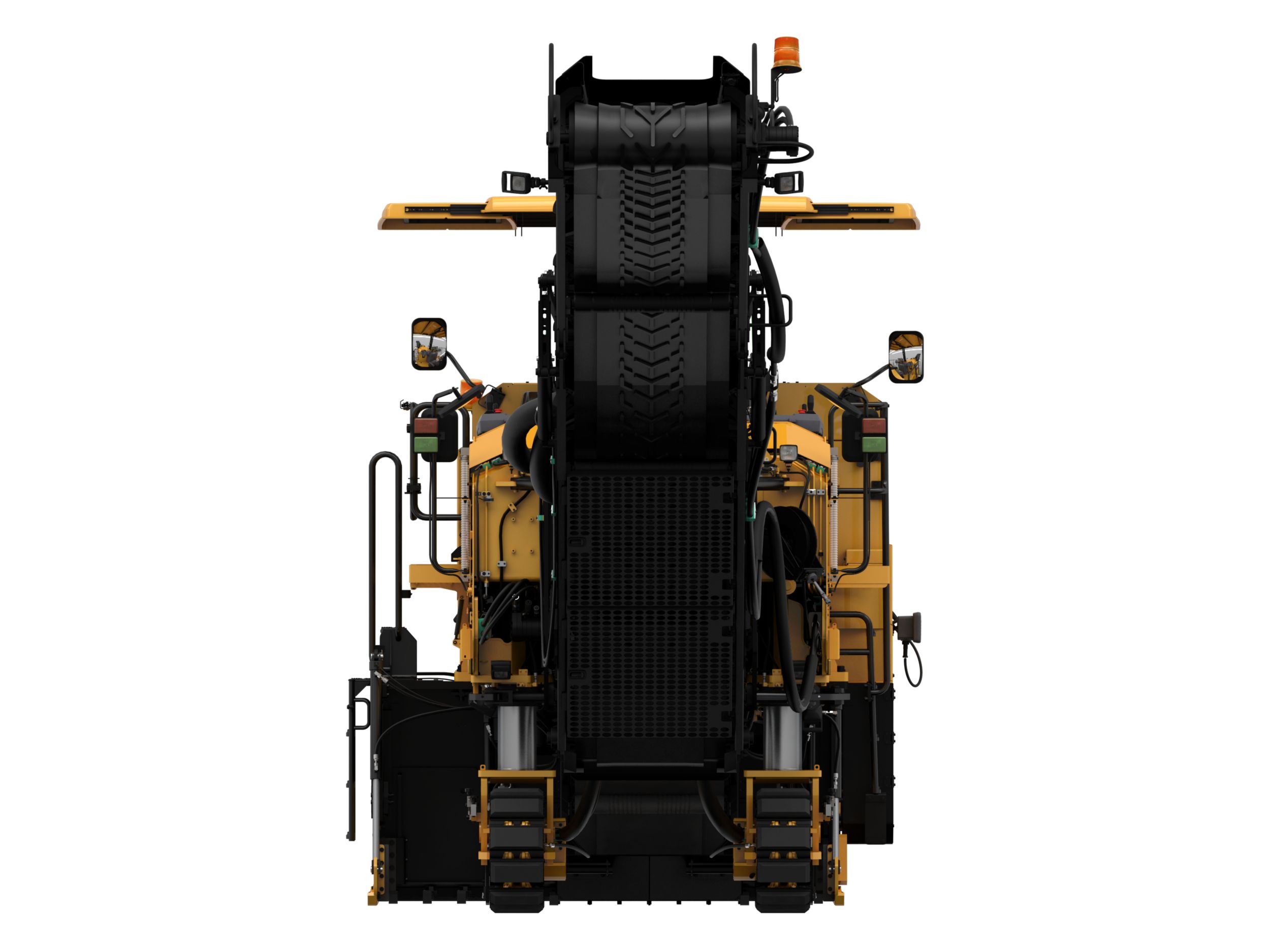

Specifications

Cutting System

- Milling Width

- 98.6in

- Maximum Milling Depth

- 13in

- Rotor Speeds

- 100 / 109 / 118 rpm

- Number of Bits

- 203

Power Train

- Rated Power

- 806HP

- Engine

- Cat C18 twin-turbo

- Maximum Travel Speed

- 3.7mile/h

- Maximum Milling Speed

- 328ft/min

Weights

- Operating Weight

- 82673lb

- Transport Weight

- 74075lb

Dimensions

- Operating Length - Conveyor Up

- 47.64ft

- Operating Width

- 11.02ft

- Height - Canopy

- 13.29ft

- Maximum Truck Clearance

- 15.94ft

- Minimum Right Cutting Radius

- 4.92ft

- Minimum Left Cutting Radius

- 6.56ft

- Conveyor Swing

- 60 degrees from center

- Transport Length

- 40.78ft

- Transport Width

- 9.88ft

- Transport Height

- 9.84ft

Service Refill Capacities

- Water Spray System Tank

- 898.2gal (US)

- Cooling System

- 27.5gal (US)

- Fuel Tank

- 292.7gal (US)

- Engine Oil

- 17.2gal (US)

- Hydraulic Tank

- 29.9gal (US)